Top selling

Contact Us

Design points of hot runner automotive plastic mould(1)

Design points of hot runner automotive plastic mould

1) The length of the hot runner wire slot is 15mm longer than the requirements of the hot runner drawing, and the rounded corner of the slot is R10 rounded, so that the wire has enough space and is not easy to break.

2) The hot runner company is required to add a circular hard pad between hot runner insulation pad and the top clamp plate, and assemble it on the top plate to prevent the expansion of the manifold after heating. After multiple cycles, the manifold will wipe the plate. The pits are created to create a virtual position, causing the hot runner nozzle to leak and the manifold to deform.

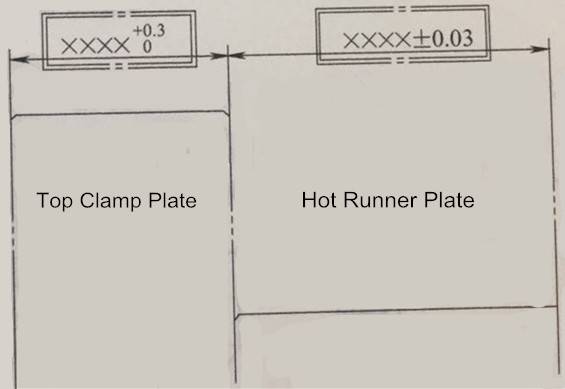

3) When ordering the mould base, the supplier is required to process the top clamp plate and the hot runner plate, and the thickness tolerance should be strictly as shown in the figure.

More information,please contact us sales@well-made.net!