Design differences between hot runner nozzles on flat and on slopes

Design differences between hot runner nozzles

on flat and on slopes

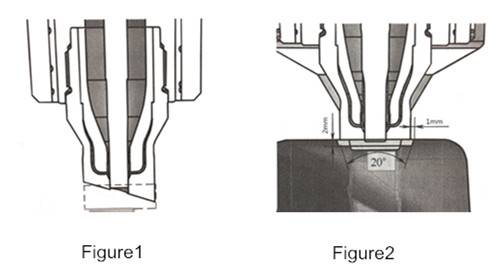

When starting the design, if you encounter the hot runner nozzle on the inclined surface of the product, you must pay attention to the length of the valve pin; if the nozzle needs to be returned to the factory for secondary processing, you must apply color (197# color) on the nozzle that needs secondary processing. The nozzle is shown to require secondary processing. As the pictures show.(figure1 & 2)

When encountering a hot runner nozzle with

a cold runner, make a vacant position just below the nozzle. The diameter

should be larger than the nozzle diameter 2mm, the depth is 1~2mm, and the

draft angle is 10° on one side, so as to avoid the nozzle heating, the length

exceeds the budget position

The nozzle is on the inclined surface, and

the length of the nozzle made by the hot runner company is required to be

higher than the lowest point of the inclined surface by 1~1.5mm. Note that the

length of the valve pin should be the same as the highest point of the

product or 0.3mm into the product.

More technical information ,welcome to contact with us! sales@well-made.net